Standard: BS EN 14651 (CMOD) / ASTM C1609 (Deflection)

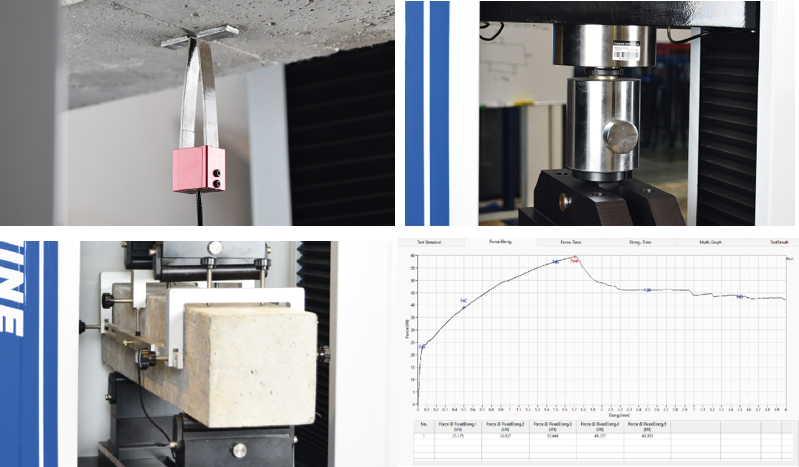

Fiber Reinforced Concrete (FRC) Testing Machine

The Fiber Reinforced Concrete Testing Machine assesses flexural strength in fiber-reinforced concrete which fulfils the CMOD and Deflection testing requirement. It boasts a sturdy frame, precise loading (hydraulic, pneumatic, or electromechanical), stable fixtures, and advanced measurement tools like strain gauges. This machine records, processes, and analyses data, empowering researchers and engineers to extract comprehensive understandings of the material's mechanical properties. To ensure operator safety and equipment integrity, the machine is fortified with an array of safety features, including emergency stop buttons and overload protection mechanisms. During testing, a concrete sample, reinforced with fibers, undergoes controlled loading until reaching its breaking point, while the measuring devices meticulously capture data.

Features of Fiber Reinforced Concrete (FRC) Testing Machine

- Fully Compatible auto-capture software customized for FRC with Load vs CMOD or Deflection curve.

- Specialized Software embedded with dedicated BS EN & ASTM programs for FRC to satisfy multiple regional FRC test requirements.

- One Touch fully automatic FCR test execution with pre-programmed speed sequence, data capture & results processing.

- Auxiliary Frame with Displacement Transducers offers precise measurement capabilities and improved data collection accuracy.

- Flexible 3 & 4 point flexural attachment for quick & easy set up to satisfy both BS EN 14651 & ASTM C1609.

- Oversized solid & super-stable main frame to ensure zero movement during test for relevant test results.

- Oil-Free electromechanical servo-controlled motor suitable for long hours FRC test without worry of excessive heat.

- The Real Result Graph illuminates FRC's flexural behaviour and mechanical properties, guiding its application across engineering fields.

- Fine Servo-Controlled perfect for precise & accurate low speed control as required for FRC test.

- High Precision CMOD & deflection transducers to mount on FRC for options to satisfy both BS & ASTM standards.

- Easy Rapid Positioning & fine control by software or remote control ensure fast FRC test execution to reduce waiting time.

- Small Footprint, space saving ergonomic convenient design for modern testing laboratories and FRC industries.

Standard: BS EN 14651 (CMOD) / ASTM C1609 (Deflection)

The European Standard, BS EN 14651 governs the assessment of flexural textile strength of concrete specimens reinforced with metallic fibers. It outlines protocols for determining essential parameters such as the limit of proportionality (LOP) and residual strength, vital for evaluating the effectiveness of fiber-reinforced concrete in structural applications. Compliance to this standard guarantees uniform testing procedures, fostering consistency and trustworthiness of outcomes in diverse laboratory settings and construction project across the European Union.

ASTM C1609, also known as the "Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading)," offers comprehensive guidelines for assessing the flexural behaviour of fiber-reinforced concrete. This standard outlines clear instructions for preparing specimens, test setup, loading procedure, and data analysis, ensuring thorough and reliable testing process. Widely acknowledged and utilised within the United States and worldwide, ASTM C1609 serves as a fundamental tool for assessing the flexural properties of fiber-reinforced concrete materials. Adhering to this standard ensures consistent testing methodologies, fostering consistency and accuracy in test results across various construction projects and material development initiatives.

Test Procedure

- Specimen Preparation: Prepare concrete specimens according to the specified dimensions and mix proportions, incorporating metallic fibers for BS EN 14651 (CMOD) and any type of fibers for ASTM C1609 (Deflection).

- Test Apparatus Setup: Position the flexural testing machine with appropriate supports and fixtures for the concrete specimens, ensuring alignment and stability.

- Loading Configuration: Apply the designated loading configuration (center-point loading for BS EN 14651, third-point loading for ASTM C1609) to the specimen using suitable loading fixtures and supports.

- Loading Procedure: Gradually apply load to the specimen until fracture, while continuously measuring the applied load and corresponding deflection.

- Data Collection: Record the maximum load sustained by the specimen and the corresponding deflection values throughout the test.

- Analysis: Calculate parameters such as flexural strength, stiffness, and toughness based on the recorded data, and determine other specific parameters as required by each standard.

- Reporting: Document the test results, including details of specimen preparation, testing conditions, and calculated parameters, in accordance with the respective standard requirements.

Technical Specifications:

| Model Number |

NL 4054 X / 001 |

| Max. Test Force |

300kN |

| Structure Type |

Twin Rigid Column with Twin High Precision Ball Screw

|

| Trailing Space |

950 mm (exclude fixtures)

|

| Width Space |

440 mm |

| Test Force Accuracy |

±0.5% |

| Test Speed Range |

0.1 - 250 mm/min |

| Load Resolution |

1/100 000 |

| Displacement Resolution |

1/1000 |

| Displacement Accuracy |

≤0.5% |

| Resolution of Metal Extenders |

1/1000 |

| Accuracy of Metal Extenders |

≤0.5% |

| Accuracy of Extenders |

±1 mm |

| Measuring Range |

0.5% - 100% Full Scale |

| Load Unit |

Gf, kgf, N, kN, Lbf, etc. |

| Curve Display |

Selectable Axial Parameters:

Y-axis - time, load, displacement, deformation, stress, strain.

X-axis - time, load, displacement, deformation, stress, strain. |

| Data Display |

Max. Force, Speed, Specimen Detail, Strength (Kpa, Mpa, N/mm, Nmm ) |

| Main Drive Unit |

Precision Servo Drive & Servo Motor |

| Safety Feature |

Emergency Stop, Overload Protection, Upper & Lower Limit Switch Load Sensor with Auto Retreat |

| Power Source |

220 ~ 240 V, 5500 W, 25 A, 1 Ph, 50 / 60 Hz, 7 Hp

|

| Dimension |

910(L) x 480(W) x 2000(H) mm |

| Approx. Weight |

780 kg |

Unit Consists Of:

| Model Number |

Parts Description |

Qty |

| NL LC – 300kNC |

300kN High Precision Load Cell (Cell Type) |

1 Unit. |

| NL 4054 X / 001 – P001 |

300kN Flexural Attachment, 3 & 4 Point Bending |

1 Unit. |

| NL 6ST – HC1 |

Handheld Magnetic Control Unit |

1 Unit. |

| TT 6ST – PC1 |

Desktop Computer Unit c/w Operation and the Software |

1 Unit |

Accessories:

| BS EN 14654 Parts Description |

| NL 4054 X / 001 - A001 |

CMOD Fork Transducer 12 x 0.001mm |

| NL 4054 X / 001 - A002 |

Datum Pieces With Sharp Edge (per pair) |

| NL 4054 X / 001 - A003 |

Displacement Transducer 20 x 0.001mm |

| NL 4054 X / 001 - A004 |

Auxiliary Frame |

| ASTM C1609 Parts Description |

| NL 4054 X / 001 - A003 |

Displacement Transducer 20 x 0.001mm (2 units) |

| NL 4054 X / 001 - A004 |

Auxiliary Frame |

Optional For Notch Cutting (BS EN 14651):

| NL 4054 X / 001 - A005 |

Guide Frame With Lock |

| NL 4054 X / 001 - A006 |

Cutting Machine With 2mm Blade |