Universal Testing Machine

NL Scientific is the leading specialist manufacturer and supplier of Universal Testing Machines to over 80+ Countries. These machines are used in research departments and quality control departments to measure the strength and product performance of raw materials such as metals, polymers, textiles, rubbers, adhesives, and food, as well as finished components.

Which Universal Tensile / Testing

Machines Should I Choose?

Key Features of a Universal Testing Machine:

- A wide range of test speeds can be performed in a variety of tests with different loading rates and acceleration profiles.

- Advanced control software for automated testing, data collection, and analysis.

- Precise load measurement capabilities to ensure accurate and reliable test results.

- Easily adjust test parameters such as speed, travel distance, and grip type.

- Control over force, speed, and displacement during testing to ensure accurate results.

- Accommodate a wide variety of sample sizes and shapes for customized testing.

- Easy-to-operate interface with intuitive controls.

Servotec Low-Force Series Single Column Universal Testing Machine

The Servotec Low-Force Series Single Column Universal Testing Machine can perform various types of mechanical tests, including tensile strength (pulling), compression strength (pushing), bending, adhesion (peel) and flexural strength tests. Single-column systems are often preferred for smaller sample sizes or lower force requirements due to their cost-saving and compact design compared to dual-column systems, which have two vertical columns for added stability and higher force capacities. The Servotec Low-Force Series Single Column Universal Testing Machine features a wide testing platform and vertical space for specimen units to fit within a 350 mm x 950 mm (exclude fixtures) clearance space with maximum force capacities of 5kN.

- Low Cost, Ready Stock, Fast Delivery, 1 Year Warranty, After Sales Technical Support

- Test Speed Range - 0.01 - 500 mm/min

- Table-Top Design

- Suitable for Elongation Materials Testing

- Exceeds ASTM and ISO Accuracy Standards - BS EN 10002-1, ISO 7500-1, ASTM A370

- Testable Items

General test item: (General display value and calculated value)

- Tensile stress, Tensile strength, Pulling strength, Stable tensile stress, Constant stress force value, Tear off the elongation, Constant stress elongation, Tear strength, Any point force value, Any point elongation, Extraction, Computation of adhesion and peak value, Pressure test, Bending test, Adhesive force stripping force test, Extraction force piercing force test, Cycle test.

Servotec High-Force Series Dual Column Universal Testing Machine

The Servotec High-Force Series Dual Column Universal Testing Machine is available in table-top and floor stand selections depending on the capacity. This machine can perform various types of mechanical tests, including tensile strength (pulling), compression strength (pushing), bending, adhesion (peel), and flexural strength tests. Dual-column systems have two vertical columns for added stability and higher force capacities which are the most cost-saving series for performing high-force testing in certain industries compared to the Electro-Hydraulic Servo Control Series. The Servotec High-Force Series Dual-Column Universal Testing Machine features a wide testing platform and vertical space for specimen units to fit within a 440 mm x 950 mm (exclude fixtures) clearance space with maximum force capacities to 300kN.

- High-Force Testing, Ready Stock, Fast Delivery, 1 Year Warranty, After Sales Support

- Capacity (kN): 10kN, 20kN, 50kN, 100kN, 200kN, 300kN

- Test Speed Range: 0.01 - 500 mm/min

- Tabletop or Floor Stand Design

- Exceeds ASTM and ISO Accuracy Standards - BS EN 10002-1, ISO 7500-1, ASTM A370, ASTM D1074

- Testable Items

General test item: (General display value and calculated value)

- Tensile stress, Tensile strength, Pulling strength, Stable tensile stress, Constant stress force value, Tear off the elongation, Constant stress elongation, Tear strength, Any point force value, Any point elongation, Extraction, Computation of adhesion and peak value, Pressure test, Bending test, Adhesive force stripping force test, Extraction force piercing force test, Cycle test.

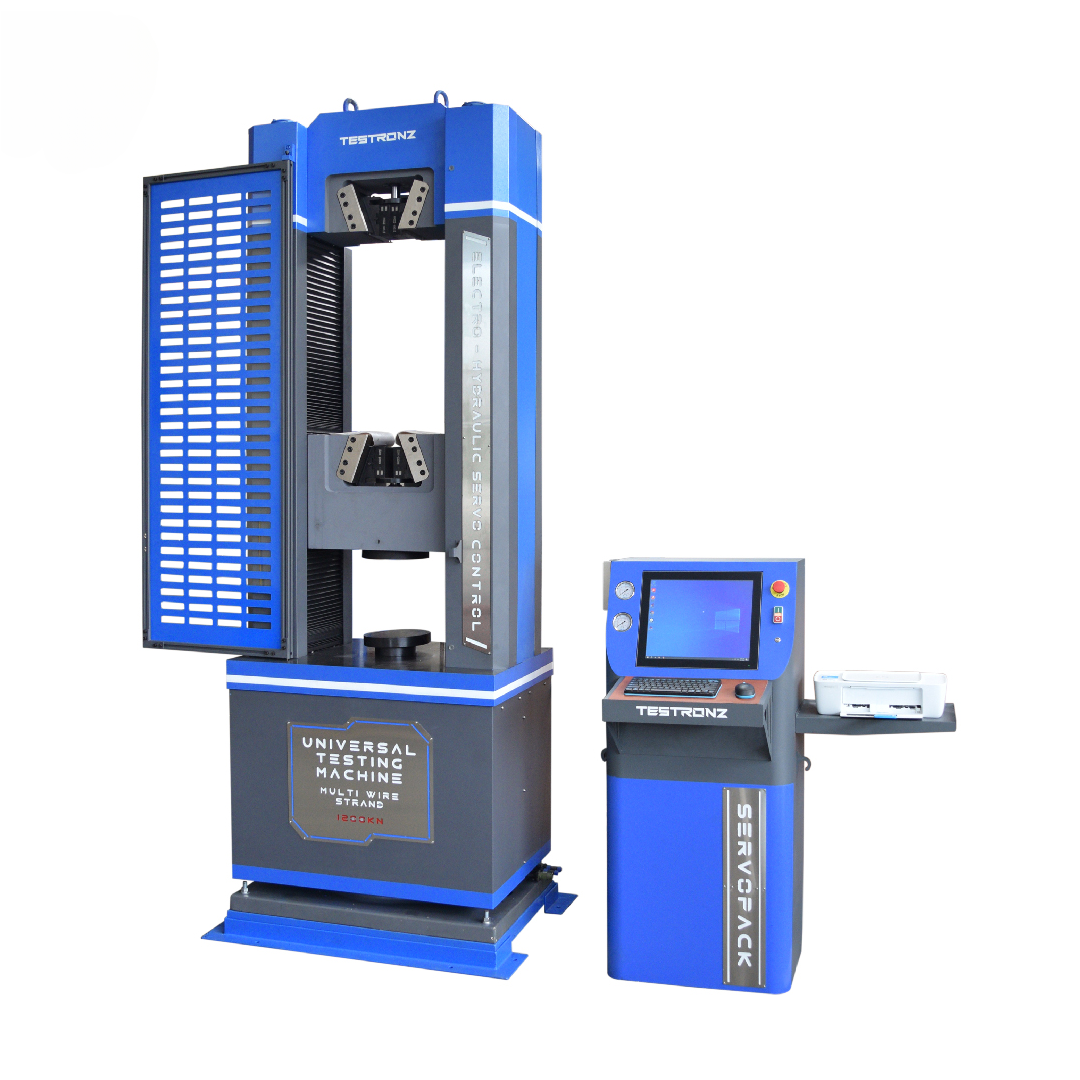

Electro-Hydraulic Servo Control Universal Testing Machine

- Competitive Pricing, Electro-Hydraulic, Ready Stock, Fast Delivery, 1 Year Warranty, After Sales Support

- Max. Compression Space - 650 mm

- Max. Tensile Space - 800 mm

- Effective Distance Between 2 Columns - 590 mm

- Test Speed Max. - 100 mm/min

- Oversize prestressed 4 columns with twin screw

- High toughness fragment safety guard with transparency sliding door

- High-precision load cell ram

- Built-in shock absorbing system on base mounting

- Console Control Unit

- Exceeds ASTM and ISO Accuracy Standards - BS EN 10002-1, ISO 7500-1, ASTM A370, ASTM D107

Software For Universal Testing Machine

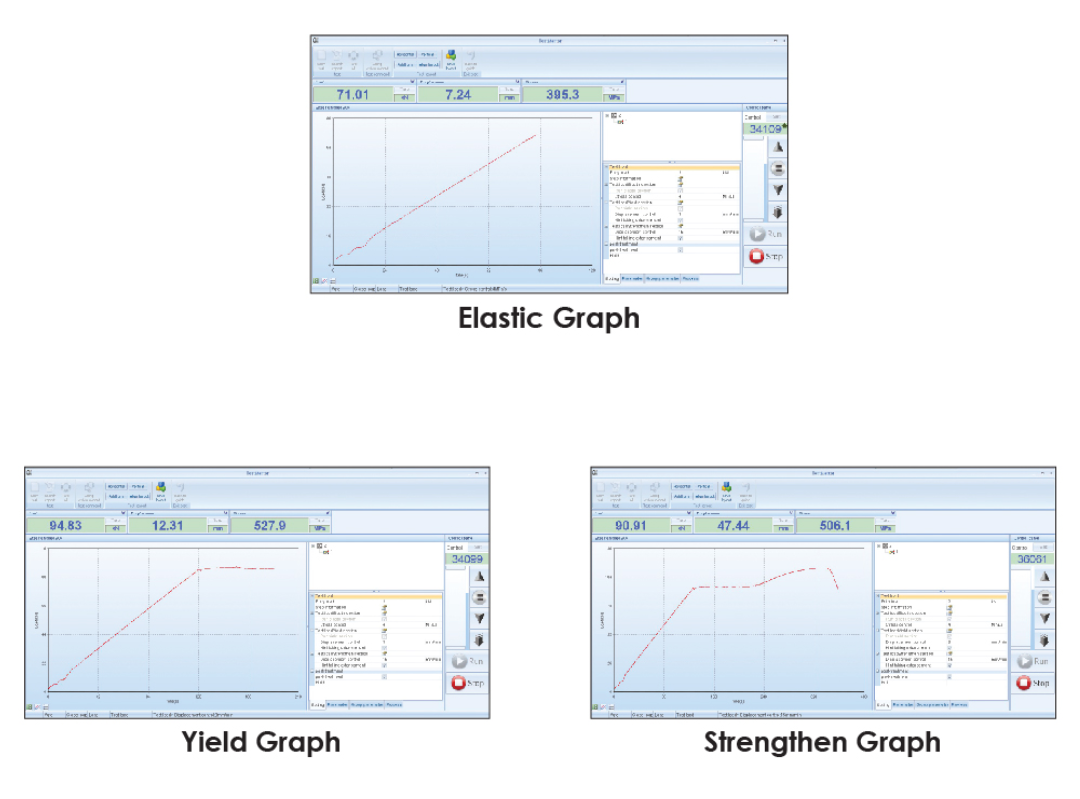

Test Master Software For Electro-Hydraulic Universal Testing Machine Series

Real-time displays test data & test status with LCD module. A Professionally designed servo control system realizes the PWM pulse width modulation control mode. It really comes up with test speed closed-loop control mode. It is controlled by single chip automatically control.

Operation Computer Screen Display Unit with the following functions:

- Test Curve Page

- User Setting Page

- Test Result Page

Operation Computer Screen Display Unit with the following functions:

- Test force display

- Break detection

- Full auto test range switching function

- Auto return function

- Peak / Break value display function

- Test conditions

Accessories for Universal Testing Machine

Extensometers: Extensometers are used to measure the deformation or strain of the test specimen during testing, particularly in tensile and compression tests. They provide accurate measurements of elongation or compression.

Load cells: Load cells are sensors used to measure the force applied to the test specimen during testing. They come in various capacities to accommodate different force ranges.