Electro-Hydraulic Servo Control Universal Testing Machines

The NL Scientific Servo Control Series Hydraulic Universal Testing Machine (UTM) adheres to industry standards such as BS EN 10002-1, ISO 7500-1, and ASTM A370, making it a versatile solution for conducting tensile, bending, compression, and other mechanical property tests on a variety of metallic and non-metallic materials. Employing electro-hydraulic servo control and electronic measurement, this UTM automates the testing process, enabling statistical analysis of results and generating customizable test reports.

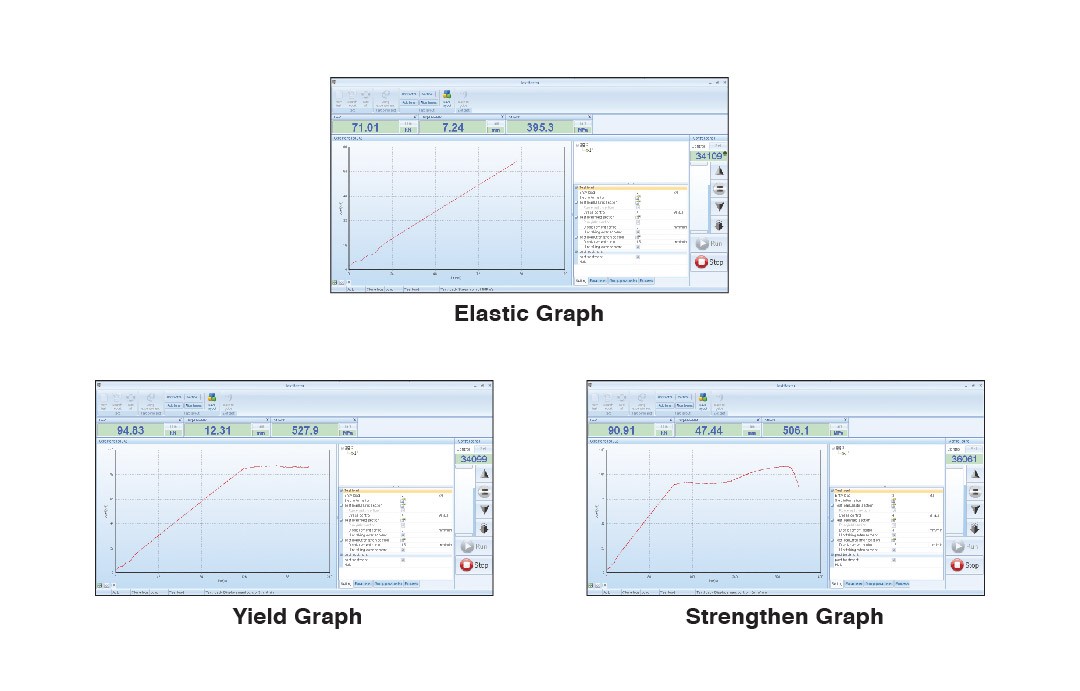

Equipped with a micro-computer for automatic data collection and processing, the NL 6000 Series UTM offers real-time display of test data and curves. It features unlimited storage of test results, batch test result report processing, and database management. The system is designed to seek multiple technical parameters, including elastic modulus, upper and lower yield strength, tensile strength, and elongation intensity. With high precision, superior performance, and user-friendly operation, it ensures reliable and accurate testing.

The UTM incorporates safety features such as an emergency stop switch, overload limit, ram-stroke limit, and various protections for the hydraulic pump motor. The control and data processing software further enhances user convenience, offering clear operation interfaces, compatibility with Microsoft Excel, and compliance with international standards. The UTM supports tension, compression, shear, cycling, and creep tests, and it allows fully customizable real-time displays, report formats, and force and stress units, meeting diverse testing requirements. Additionally, it provides advanced protection features, USB communication, Ethernet connectivity, and a wide range of grips and fixtures for different testing needs.

300KN UNIVERSAL TESTING MACHINE

600KN UNIVERSAL TESTING MACHINE

1000KN UNIVERSAL TESTING MACHINE

1200KN UNIVERSAL TESTING MACHINE

1500KN UNIVERSAL TESTING MACHINE

2000KN UNIVERSAL TESTING MACHINE

COMPRESSION PLATEN

Compression platens serve as essential components for conducting compression tests across diverse materials and components. When integrated into a Universal Testing Machine, these platens facilitate a versatile array of tests, enabling the precise determination of compression modulus, compression strength, and compression yield strength. Featuring a diameter of 150xh50mm, these platens provide a standardized and effective means to assess the compressive properties of various specimens with accuracy and reliability.

EXTENSOMETER

Hydraulic grips stand out for their exceptional safety features, ensuring a secure testing environment. Specifically designed for pulling cylinder samples with diameters ranging from 8 to 32 mm, these grips include an independent hydraulic power unit operating at 400 bars for optimal performance. It's worth noting that separate orders for jaw faces are necessary when dealing with flat samples, enhancing customization options based on specific testing requirements.

HYDRAULIC GRIPS

A high-precision load cell, engineered for both compression and tension, is available in a range of capacities from 20 to 100 tons. Crafted with a nickel-plated alloy body and hermetic sealing, this load cell ensures dependable precision even in rigorous industrial settings. Ideal for applications in force testing machines and tensile tear test machines, it stands as a robust solution for accurate and reliable measurements across various testing scenarios.

LOAD CELL

A high-precision load cell, engineered for both compression and tension, is available in a range of capacities from 20 to 100 tons. Crafted with a nickel-plated alloy body and hermetic sealing, this load cell ensures dependable precision even in rigorous industrial settings. Ideal for applications in force testing machines and tensile tear test machines, it stands as a robust solution for accurate and reliable measurements across various testing scenarios.

HAND CONTROL

This handheld unit serves the essential purpose of positioning the upper cross-head, tailoring it to the specific height of the sample, and securely tightening the grippers before the commencement of testing. Its ergonomic design and functionality streamline the pre-testing process, ensuring precision and ease of use for efficient sample preparation.

CONTROL & DATA PROCESSING SOFTWARE

*User friendly & easily due to clear and brief operation – operation interface

*Automatically save the test conditions & results

*User define test curves including : Stress / Strain, Force / Elongation, Strength / Time to suit various requirement

*Individual or combine display test curves on the same screen to compare with other several data at the same time

*Compatible with Microsoft Excel by import or export function

*Base of testing with digital sample break detection, auto ranging, auto calibration, quick tare & auto return facilities

*Exceeds all International Standards for accuracy, ASTM, DIN, ISO, JIS, EN, GB…etc

*Tension, Compression, Shear, Cycling & Creep Test facilities

*User define Real Time Display Including Load, Stress, Elongation, Strain, Speed or Time

*Advanced protection features with software setting or / & hardware switch upper & lower limit setting

*Operation fully control by computer

*USB communication system & ethernet

*Grips & fixtures for tension, compression, flexural, shear & products testing available

*Fully user define report including Report Sheet, Label, Chart & Bitmap or JPG

*Report sheet consist of Load, Elongation, Yield, Break, Stress Modulus, Strain, Tear Strength, Peel Strength etc *Force display unit : kN,N,tons, & mN

*Stress display unit : GPa,Mpa,Pa,psi,N/sq.mm,Kg/sq.mm & Tons/sq.inch

*User define Yield Strength, Young Modulus, Offset Setting, Graph Offset, Export & Import test data, …etc

Computer Screen Display unit with the following functions 、

*Test force display

*Break detection

*Full auto test range switching function

*Auto return function

*Peak / Break value display function

*Test conditions

SAFETY FEATURES

The system include with the followings safety features

*Emergency stop switch

*Overload limit *Ram-stroke limit

*Hydraulic pump motor over-current & over heating protection

*Leak / over current protection

*Automatic stop control

*Safety Guard

TOP FEATURE

- Dual Test Space Design: Enables seamless transitions between tension and compression test setups, eliminating the need to remove heavy fixtures for enhanced safety and efficiency.

- Hydraulic Wedge Action Tensile Grips: Integrated into the load frame crosshead with jaws, ensuring a secure grip during tests.

- Open Front Grip Approach: Improves operator safety and throughput, accommodating a versatile selection of grip jaws for a wide range of sample sizes.

- Force Range: 100:1 force range allows the use of the load cell to 1% of capacity without compromising accuracy.

- Test Force Accuracy: ±1%, ensuring reliable and precise measurement of applied forces.

- Data Acquisition Rate: Rapid 1,000 Hz data acquisition rate for precise and real-time data capture.

- Test Speed: 100mm/min for controlled and consistent testing procedures.|

- Digital Position Encoder: Ensures accurate position tracking during testing processes.

- Measuring Range: Spans from 1% to 100% of the full scale, accommodating a broad range of testing requirements.

- Control Options: Offers constant speed, constant load rate, as well as position and load control for enhanced testing flexibility.

ADVANTAGES OF HYDRAULIC UNIVERSAL TESTING MACHINE

- Central Hydraulic Drive: Utilizes a single central hydraulic drive (differential actuator) for efficient and reliable testing.

- Adaptable Test Area: Optional adjustable top crosshead accommodates customer-specific requirements, enhancing versatility.

- Ergonomic Design: Ergonomic operating height facilitates easy specimen feeding, ensuring user-friendly operation.

- High-Resolution Measurement Technology: Employs high-resolution and channel-synchronized measurement technology for extremely accurate material characteristic determination.

- Load Signal Resolution: Provides consistent load signal resolution over the full range, eliminating the need for range-switching.

- Calibrated Force Measurement: Force measurement via a DMS load cell calibrated in accordance with ISO 7500-1 in Class 0.5 and Class 1, ensuring precision.

- Wide Measurement Range: Allows precise determination of low test loads without the need for re-equipping the testing machine.

- Vibration Damping Design: Set on vibration damping rubber mats, eliminating the need for a special foundation.

- User-Friendly Operation: For standard testing with NL Scientific Servo Control software, operator involvement is reduced to the push of a button.

- Modular Design: Features a modular design throughout the system, enabling the use of a wide variety of extensometers, specimen grips, and other test fixtures from the NL Scientific accessory range.

- Easy Installation of Test Fixtures: Additional test fixtures can be easily installed via a T-slot or screw system to meet new testing requirements.

- Tailored to Customer-Specific Needs: The machine can be customized to customer-specific requirements, including test devices, specimen grips, test speed ranges, and testing software.

Order A Universal Testing Machine

With the advance features and capabalities, these machines are perfect for businesses of all size that need high-quality testing equipment for material and engineering tests.