What is Compression Testing?

Compression testing is a fundamental mechanical evaluation that, alongside tensile and flexion tests, plays a crucial role in understanding material behavior under increasing crushing loads. Conducted using compression testing machines or universal testing machines with specialized fixtures, these tests involve applying compressive pressure to specimens, often in cuboid or cylindrical geometries. The resulting data provides essential insights into a material's safety, durability, and integrity, revealing properties such as the elastic limit, proportional limit, yield point, yield strength, and, in specific materials, compressive strength.

These tests find widespread applications across various industries, including plastic tubes, pipes, foam materials, paper, cardboard, compression springs, medical implants, packaging, and composite materials. By characterizing a material's response to compressive loading, compression tests contribute to a comprehensive understanding of its mechanical properties. The test data, presented in stress-strain diagrams, showcases key parameters like the elastic limit, proportionality limit, and yield point. Essentially the opposite of tensile tests that pull specimens apart, compression tests offer versatility, allowing examinations on machined material specimens or full-size and scale models of actual components. Common types of compression tests include the top-load (crush) test, flexure (bend) test, and spring test, collectively providing valuable information for design, quality control, and material selection across diverse industrial sectors.

What Is Compression Test Machines

Compression test machines, or universal testing machines (UTMs), evaluate static compressive strength characteristics of various materials, products, and components. Measure parameters like compression strength, yield strength, deflection, and modulus, each compression tester is customized by our engineers to align with specific test requirements. The modular design of our machines offers versatility, allowing for additional applications, such as tensile, cyclic, shear, flexure, bend, peel, and tear through appropriate fixtures.

Compression test machines, equipped with components like load cells, crossheads, compression test tools, electronics, and a drive system, utilize advanced testing software aligned with industry standards such as ASTM and ISO. Material considerations and adherence to standards are crucial in equipment selection. By measuring force until a specified load or distance is reached, these machines offer essential insights into a material's strength and deformation behavior, predicting real-world performance, making these machines indispensable for comprehensive material testing and analysis.

*Choose a universal test machine if you need more flexibility or a compression only test machine if you will only be performing compression tests for the foreseeable future.

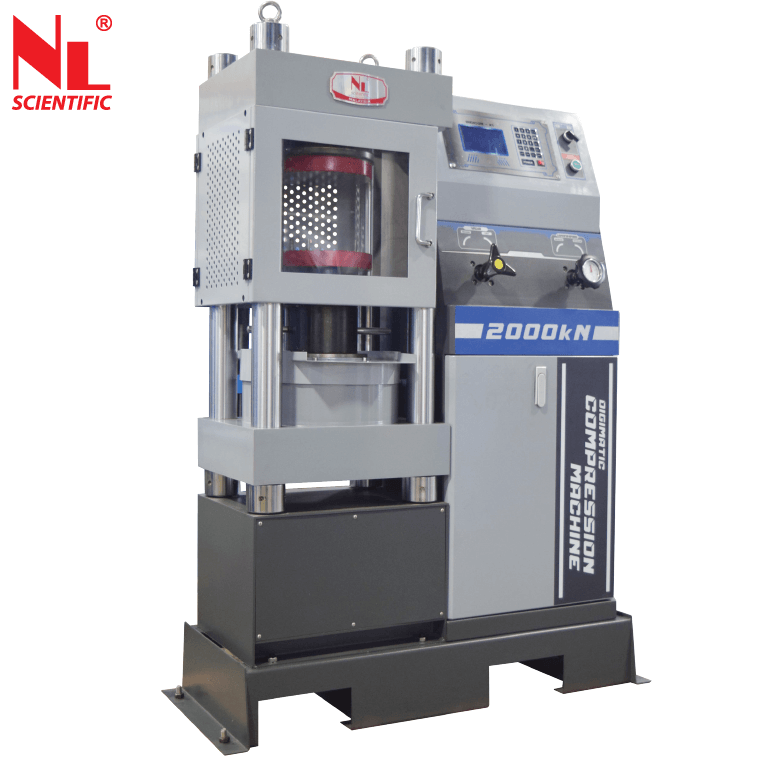

Choose our available compression testing machines with load

capacities of 2000kN, 3000kN, 5000kn. Series includes Fully-Automatic Computerized, Automatic, Digimatic, and Analogue.

Choose our available tensile machines with load capacities

of 10kN, 20kN, 50kN, 100kN, 200kN, 300kN, 600kN, 1000kN, 1200kN, 1500kN, and 2000kN.

Why Perform Compression Test?

Compression testing stands as an indispensable cornerstone in evaluating materials, components, and end products throughout various manufacturing stages. Its primary function revolves around assessing the capacity of materials to endure the specific mechanical forces anticipated within their intended applications. Whether it's examining the resilience of car windshields, the durability of construction concrete beams, or the comfort factor of foam used in seating arrangements, a material's suitability heavily depends on its capacity to endure diverse mechanical forces, usage cycles, durations, and environmental conditions.

Materials often exhibit an inverse relationship between tensile and compressive strength, emphasizing the criticality of compression testing, especially for brittle substances like metals, plastics, ceramics, composites, and cardboard utilized in load-bearing scenarios. Unlike tests focusing on material properties, compression tests directly evaluate finished products like tennis balls, water bottles, or furniture, offering crucial insights into their compressive strength. For instance, engineers seeking to optimize materials while maintaining product strength rely on compression tests to strike a delicate balance—ensuring items like thinner-walled water bottles remain resilient during transport and stacking on pallets.

Moreover, compression testing transcends the realms of research and development, playing a pivotal role in quality assurance protocols. Ensuring that batches of finished products meet prescribed compressive specifications is not merely a safety consideration but also integral for business credibility. Defective products pose risks to users and can lead to substantial setbacks for manufacturers, including delays, revenue losses, and reputational damage. In essence, the meticulous conduct of compression tests underpins the integrity, safety, and efficiency of materials and products, providing crucial insights into their response to compressive forces. This data aids in material selection, optimizing product designs, and ensuring quality control, contributing significantly to safety, cost-efficiency, and overall performance across diverse industries.

How to Perform Compression Test with Universal Testing Machine?

Compression tests are performed on universal testing machines, also known as compression testing machines. Universal testing machines are the most flexible and versatile systems designed for evaluating the characteristics of various materials and components that can perform more than just compression tests. Universal Testing Machine can easily perform other test applications such as tensile, cyclic, shear, flexure, bend, peel, and tear by simply adding appropriate fixtures. These machines, available in single or dual-column frames with Load Cells, Testing Software, and specialized Platens, cater to a broad force capacity spectrum, from as low as 0.02 N to as high as 2,000 kN. NL Scientific's range, spanning from the Tabletop Servo Control Series for lower force tests to the NL Scientific’s Industrial Servo Control Hydraulic Series for higher force applications, offers adaptability through different fixtures to comprehensively analyze products, components, or materials.

|

|

|

|

The twin-column frame is the structural component of the UTM that provides support for the various testing components. It typically consists of two vertical columns that support the crosshead, where the load is applied to the specimen. |

|

|

The Magnetic Control Unit is responsible for controlling and adjusting the speed and movement of the crosshead. It is a magnetic particle brake system that provides precise control over the loading and unloading phases during a test. |

|

|

The load cell is a crucial component that measures the force or load applied to the specimen during a test. It converts the mechanical force into an electrical signal that can be interpreted and recorded by the testing machine. |

|

|

The auxiliary unit refers to additional components that enhance the capabilities of the UTM. This includes accessories like grips, fixtures, or heating/cooling systems that are specifically designed for different types of tests or materials. |

|

|

The emergency stop is a safety feature that allows the immediate cessation of the testing procedure in case of any unexpected or dangerous situations. It is crucial for preventing damage to the testing machine, and specimens, or ensuring the safety of operators. |

|

|

6. Software The software is the interface that controls the UTM, allowing users to set up, monitor, and analyze tests. It provides a user-friendly platform to input test parameters, start and stop tests, and collect data. |

How to Perform Compression Test with Compression Testing Machine?

Compression Testing Machines, also known as Compression Only Machine, are use to perform compression used to test the compressive strength of materials. Compressive strength is a measure of the ability of a material, such as concrete, to withstand compressive loads without breaking or failing. The testing machine typically consists of a hydraulic pump that applies a compressive force to a cylindrical concrete specimen. The force is applied at a constant rate until the specimen fails or reaches a predetermined maximum load. These machines, available in force capacities ranging from 2000 kN to 5000 kN with multiple series including, Analogue, Automatic, to Computerized Series.

Purpose of a Concrete Compression Machine

The Compression Testing Machine (CTM) is a crucial tool for evaluating material quality through compression resistance analysis. It operates by applying a standard static force and displacement rate to measure the compressive strength of various materials. With diverse models tailored for specific testing needs, ranging from gas cylinders to units excluding torsional forces, selecting the right CTM depends on the material and desired test outcomes, including non-destructive evaluation capabilities.

In engineering and materials testing, the CTM plays a pivotal role in examining mechanical properties and load-bearing capacities of materials like concrete and sheet metal. Its primary goal is to determine the maximum stress a material can withstand before failure or deformation, a critical metric for assessing strength and suitability. As a linchpin in quality control, CTMs ensure materials meet design specifications, enhancing safety and reliability in various applications.

ASIA LEADER IN

MATERIAL TESTING EQUIPMENT

Selecting a Compression Test Machine

Choose a universal test machine for the most flexibility which can easilty perform other test applications such as tensile, cyclic, shear, flexure, bend, peel, and tear by simply adding appropriate fixtures. Choose a compression only test machine if you will be performing compression tests application only or a higher compressive load compared to universal testing machines.

All Compression Only Machines Series

AUTOMATIC COMPRESSION TESTING MACHINE

COMPUTERIZED COMPRESSION TESTING MACHINE (FULLY AUTOMATIC)

COMPUTERIZED FULLY AUTOMATIC WELDED FRAME COMPRESSION MACHINE

ANALOGUE COMPRESSION TESTING MACHINE

DIGIMATIC COMPRESSION MACHINE

Type of Compression-Only Machine Series

- Analogue Compression Testing Machine:

- Technology: Analog machines use traditional analog gauges or meters to display test measurements such as force or displacement.

- Readout: Results are read directly from the analog gauges, which may involve manual interpretation.

- Controls: Manual control knobs or levers are typically used to adjust testing parameters.

- Data Recording: Analog machines may require manual recording of test data.

- Digital Compression Testing Machine:

- Technology: Digital machines use digital sensors and displays to measure and present test data.

- Readout: Results are displayed digitally, providing easier and more precise readings compared to analog displays.

- Controls: Digital controls, often with keypads or touchscreens, offer more precise and user-friendly adjustment of testing parameters.

- Data Recording: Some digital machines may have built-in data recording capabilities for later analysis.

- Automatic Compression Testing Machine:

- Automation: Automatic machines are designed to perform tests with a higher degree of automation, reducing the need for manual intervention.

- Testing Procedures: These machines can automatically apply the load, control the testing process, and even stop the test when specific conditions are met.

- Data Logging: Automatic machines typically have integrated data logging capabilities, recording key parameters during the test automatically.

- Automatic Compression Testing Machine, Computerized:

- Computer Integration: This type of machine combines automation with computerized controls, allowing for more advanced and sophisticated testing procedures.

- Software Control: Computerized systems often come with dedicated software that allows for precise control, real-time monitoring, and extensive data analysis.

- Data Visualization: Results are often graphically displayed on a computer screen, offering a more detailed and comprehensive view of the material's behavior.

- Data Storage: Computerized systems usually have advanced data storage capabilities, enabling users to store, retrieve, and analyze large sets of test data.

2000 kN Compression-Only Machine Specification

|

Model Number |

NL 4000 X / 009N |

NL 4000 X / 032G |

NL 4000 X / 016U |

NL 4000 X / 034N |

|

Model Type |

Analogue - Eco Smartz |

Digimatic |

Automatic |

Fully-Automatic, Computerized |

|

Max. Vertical Clearance |

415 mm |

400 mm |

425 mm |

382 mm |

|

Max. Horizontal Clearance |

270 mm |

285 mm |

270 mm |

270 mm |

|

Capacity |

2000 kN |

|||

|

Compression Platen Diameter |

295 mm |

216 mm |

295 mm |

295 mm |

|

Piston Ram Diameter |

250 mm |

250 mm |

250 mm |

250 mm |

|

Piston Ram Travel |

50 mm |

50 mm |

50 mm |

60 mm |

|

Column Diameter |

Ø66.5 mm |

Ø65 mm |

Ø70 mm |

Ø70 mm |

|

Accuracy |

Class 2 |

Class 1 |

Class 1 |

Class 1 |

|

Product Dimension (mm) |

965 (L) x 610 (W) x 1300 (H) |

1010 (L) x 430 (W) x 1480 (H) |

970 (L) x 610 (W) x 1300 (H) |

1450 (L) x 620 (W) x 1600 (H) |

|

Approx. Product Weight |

782.5 kg |

625 kg |

783 kg |

900 kg |

|

Power |

220 V, 2.5 Amp, 50 / 60 Hz, 1 Ph |

AC220 V, 1Ph, 6A, 50/60 Hz, |

220~240 V, 750 W, 1 Ph, 50 / 60 Hz |

220~240V, 50/60 Hz, 6A, 1Ph, 750 W |

3000, 5000 kN Compression-Only Machine Specification

|

Model Number |

NL 4000 X / 018U |

NL 4000 X / 035N |

NL 4000 X / 020 |

NL 4000 X / 025 |

|

Model Type |

Automatic |

Fully-Automatic, Computerized |

Fully-Automatic, Computerized, Welded Frame |

Fully-Automatic, Computerized, Welded Frame |

|

Max. Vertical Clearance |

370 mm |

373 mm |

350 mm |

435 mm |

|

Max. Horizontal Clearance |

320 mm |

270 mm |

290 mm |

580 mm |

|

Capacity |

3000 kN |

|||

|

Compression Platen Diameter |

295 mm |

295 mm |

300 mm |

300 mm |

|

Piston Ram Diameter |

290 mm |

250 mm |

300 mm |

440 mm |

|

Piston Ram Travel |

50 mm |

60 mm |

50 mm |

50 mm |

|

Accuracy |

Class 1 |

Class 1 |

Class 1 |

Class 1 |

|

Column Diameter |

Ø73 mm |

Ø77.5 mm |

Ø80 mm |

Frame: 750 (L) x 660 (W) x 1500 (H) |

|

Product Dimension (mm) |

1020 (L) x 650 (W) x 1300 (H) |

1450 (L) x 620 (W) x 1600 (H) |

960 (L) x 500 (W) x 1200 (H) |

|

|

Approx. Product Weight |

905 kg |

1000 kg |

625 kg |

2800 kg |

|

Power |

240 V, 750 W, 5 Amp, 50 / 60 Hz, 1 Ph |

220~240V, 50/60Hz, 1Ph, 6 Amps. |

AC220 V, 1Ph, 6A, 50/60 Hz, |

220 V, 2.5 Amp, 50 / 60 Hz, 1 Ph |

All Compression Testing Machines Series

3KN UNIVERSAL TESTING MACHINE

10KN UNIVERSAL TESTING MACHINE

50KN UNIVERSAL TESTING MACHINE

100KN UNIVERSAL TESTING MACHINE

200KN UNIVERSAL TESTING MACHINE

300KN-2000KN UNIVERSAL TESTING MACHINE

Compression Testing Fixtures For Universal Testing Machine

Fixed Platen

Self Aligning Platens

High-Temperature Platen

Specification for Universal Testing Machine

|

Model Number |

TT6000 X / 032N |

TT6000 X / 020N |

TT6000 X / 019N |

TT6000 X / 018N |

TT6000 X / 024N |

TT6000 X / 023N |

|---|---|---|---|---|---|---|

|

Max Test Force |

10kN |

20kN |

50kN |

100kN |

200kN |

300kN |

|

|

1000kgf |

2000kgf |

5000kgf |

10000kgf |

20000kgf |

30000kgf |

|

Structure Type |

Twin Rigid Column with Twin High Precision Ball Screw |

|||||

|

Trailing Space |

950 mm (exclude fixtures) |

|||||

|

Width Space |

350 mm |

350 mm |

400 mm |

440 mm |

440 mm |

440 mm |

|

Test Force Accuracy |

±0.5% |

±0.5% |

±0.5% |

±0.5% |

±0.5% |

±0.5% |

|

Test Speed Range |

0.01 - 500 mm/min |

0.01 - 500 mm/min |

0.01 - 500 mm/min |

0.1 - 250 mm/min |

0.1 - 250 mm/min |

0.1 - 500 mm/min |

|

Load Resolution |

1/100 000 |

1/100 000 |

1/100 000 |

1/100 000 |

1/100 000 |

1/100 000 |

|

Displacement Resolution |

1/1000 |

1/1000 |

1/1000 |

1/1000 |

1/1000 |

1/1000 |

|

Displacement Accuracy |

≤0.5% |

≤0.5% |

≤0.5% |

≤0.5% |

≤0.5% |

≤0.5% |

|

Resolution of Metal Extenders |

1/1000 |

1/1000 |

1/1000 |

1/1000 |

1/1000 |

1/1000 |

|

Accuracy of Metal Extenders |

≤0.5% |

≤0.5% |

≤0.5% |

≤0.5% |

≤0.5% |

≤0.5% |

|

Accuracy of Extenders |

±1 mm |

±1 mm |

±1 mm |

±1 mm |

±1 mm |

±1 mm |

|

Measuring Range |

0.5% - 100% Full Scale |

|||||

|

Load Unit |

Gf, kgf, N, kN, Lbf, etc. |

|||||

|

Curve Display |

Selectable Axial Parameters: Y-axis - time, load, displacement, deformation, stress, strain. X-axis - time, load, displacement, deformation, stress, strain. |

|||||

|

Data Display |

Max. Force, Speed, Specimen Detail, Strength (Kpa, Mpa, N/mm, Nmm) |

|||||

|

Main Drive Unit |

Precision Servo Drive & Servo Motor |

|||||

|

Safety Feature |

Emergency Stop, Overload Protection, Upper & Lower Limit Switch Load Sensor with Auto Retreat |

|||||

|

Power Source |

220 ~ 240V, 600W, 4A, 1Ph, 50/60Hz, 0.8Hp |

220 ~ 240V, 1500W, 5A, 1Ph, 50/60 Hz, 2Hp |

380 ~ 415V, 1500W, 5A, 1Ph, 50/60 Hz, 2Hp |

|||

|

Product Dimension |

660(L) x 450(W) x 1700(H) mm |

606 x 405 x 1625 mm |

490 x 795 x 1750 mm |

910 x 480 x 2000 mm |

910 x 480 x 2000 mm |

910 x 480 x 2000 mm |

|

Approx. Weight |

186 kg |

220 kg |

250 kg |

500 kg |

500 kg |

500 kg |

Compression Testing Standards

Standards set by renowned organizations like ASTM and ISO serve as the cornerstone of compression testing across industries. These meticulous guidelines establish parameters and expected outcomes for various raw materials, from metals and concrete crucial for infrastructure projects to refined products like medical devices and electronics. By adhering to these standards, materials and end-products within the supply chain are ensured to possess consistent mechanical properties, mitigating the risk of failure in their intended applications.

For instance, ASTM D3574, observed by industries such as furniture, automotive, and mattress manufacturing, focuses on assessing the indentation force deflection of polyurethane foam. This test precisely measures the foam's initial softness when compressed to 25% of its original thickness, followed by gauging its supportiveness at 65% compression. Automotive seating engineers rely on this data to specify the desired indentation force deflection for their products. Manufacturing locations rigorously conduct these tests throughout production, ensuring uniform softness and supportiveness in every seat manufactured. Given the significant implications of product failure on cost and safety, companies are strongly advised to invest in high-caliber, precise testing equipment. This investment allows them to seamlessly verify whether their products align with the applicable standards, reinforcing reliability and meeting quality benchmarks.

ASTM Standards:

ASTM C109: Specifically for testing 2-inch concrete cubes to assess compression.

ASTM C170: Evaluates the compression strength of dimension stone materials.

ASTM C365: Tailored for compression testing of sandwich core materials.

ASTM C39: Focuses on compression testing of concrete cylinders.

ASTM D1621: Assesses the compressive properties of rigid cellular plastics.

ASTM D2844: Measures moisture exudation in compacted soils.

ASTM D3410: Determines the compressive strength of polymer matrix composites.

ASTM D575-91: Standard test method for assessing rubber properties under compression.

ASTM D6484: Evaluate the open hole compressive strength of polymer matrix composite laminates.

ASTM D6641: Assessing compressive properties of polymer matrix composites using a combined loading compression (CLC) test fixture.

ASTM D695: Evaluates compression testing for rigid plastics.

ASTM D7137: Specifically measures compressive residual strength properties of damaged polymer matrix composite plates.

ASTM F1306: Measures the slow rate penetration resistance of flexible barrier films and laminates.

ASTM D3574: Standard test methods for flexible cellular materials.

ISO Standards:

ISO 11608: Concerns needle-based injection systems.

ISO 604: Assesses the compressive properties of plastics.

ISO 7886: Tests sterile hypodermic syringes.

ISO 844: Focuses on compression properties of rigid cellular plastics.

Other Standards:

AASHTO T 190: Measures resistance R value and expansion pressure of compacted soils.

BSS 7260: Assesses post-impact compressive strength of composite laminates.

Caltrans Test Method (CTM) 301: Conducts moisture exudation tests for compacted soils.

Order A Compression Testing Machine

With the advance features and capabalities, these machines are perfect for businesses of all size that need high-quality testing equipment for material and engineering tests.

Read More About Compression Testing Machine

- What is Universal Testing Machine?

- Benchtop Universal Testing Machines

- Floor Standing Universal Testing Machines

- Installation of Universal Testing Machines: A Comprehensive Guide

- Universal Testing Machine Training

- Concrete Compression Testing Machines

- ASTM Standard Compression Testing Machines

- EN Standard Compression Testing Machines