Sieve Shakers

Discover the efficiency of sieve shakers, engineered to autom ate particle agitation for precise separation and sizing distribution across various materials, ensuring adherence to stringent quality control and assurance standards. These shakers offer unparalleled advantages, including consistent, accurate, and repeatable separations, surpassing the capabilities of manual sieve shaking methods. Moreover, they significantly reduce testing time, making your processes more efficient.

For comprehensive coarse aggregate separation solutions, explore our di verse range of Scr een Shakers. If you're uncertain about which shaker best suits your requirements, you can refer to our comparison chart or explore our informative blog post, titled "A Comprehensive Guide to Choosing the Right Shaker," to make well-informed decisions. Discover the world of effortless particle analysis with our cutt ing-edge sieve shakers.

Sieve Shakers Ensuring Precise Particle Size Analysis

Tapping Shakers

- These shakers utilize circular movements and periodic two-way tapping to reposition particles and prevent clogging. Mechanical tapping enhances the passage of particles, especially fine ones. Our models come with various primary actions like vibratory, circular, and orbital, catering to a wide range of m aterials.

Rotary Sifters

- Within these sifters, a slanted cab inet encases a stack of sieves, and rollers rotate the sieves while hammers gently tap on them, facilitating the passage of particles of similar sizes. Rotary sifters offer a noise-free and dust-free operation, making them suitable for materials ranging from No. 4 (4.75mm) to No. 635 (20μm).

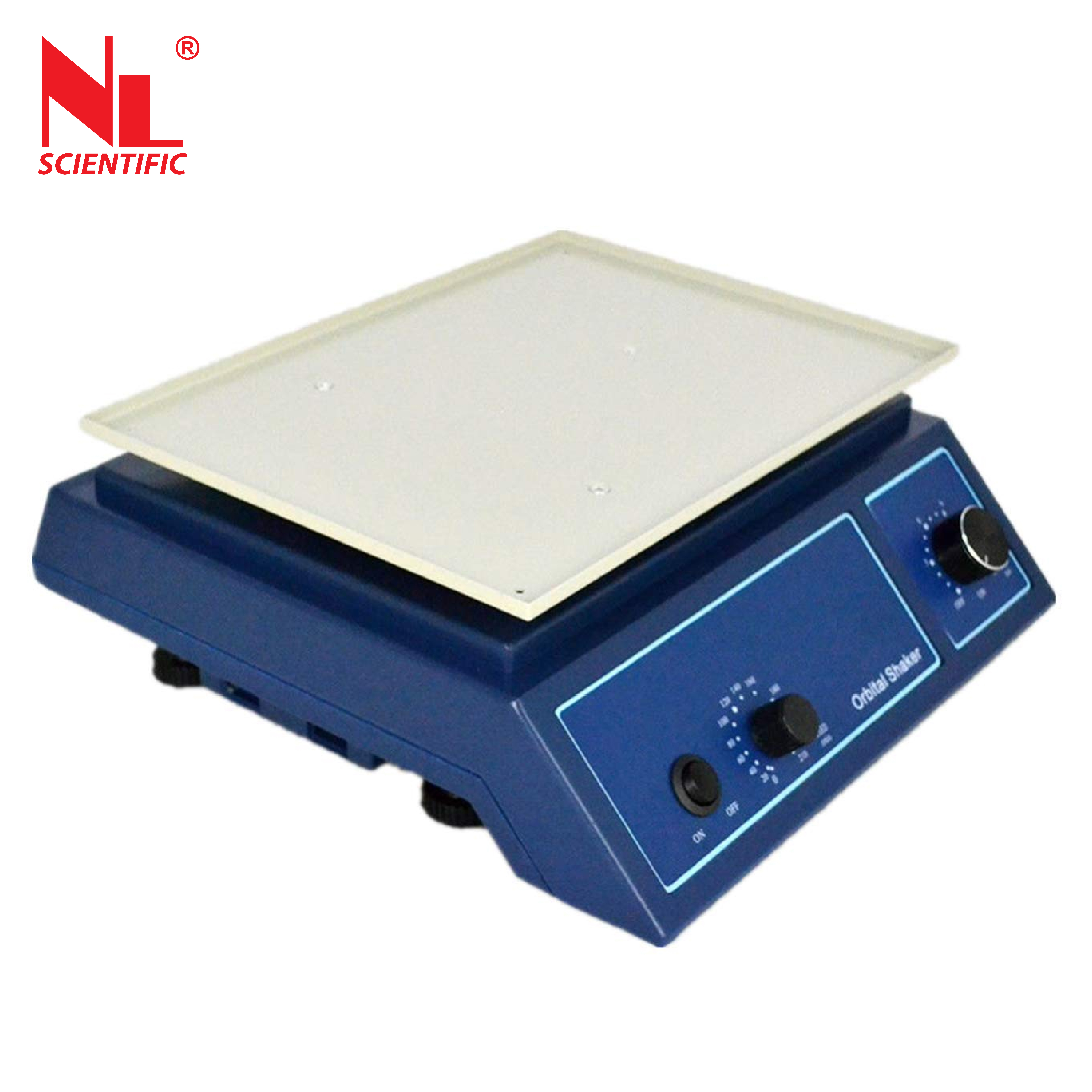

Orbital Shakers

- Orbital shakers replicate manual sieving, making them an excellent choice for materials that flow freely. These shakers suspend the sieves, and their base moves in an orbital pattern, causing particles to pass through sieve openings.They are compatible with materials within the range of No. 4 (4.75mm) to No. 200 (75μm) and come with timer options in both m anual and digital formats.

Vibratory Shakers

- These shakers utilize electromagnetic energy to create a fluidized bed of materials. You can fine-tune the vibration amplitude and frequency to enhance performance for materials spanning from No. 10 (2mm) to No. 635 (20μm). Certain models also provide a pause function, akin to tapping, to improve the reorientation of particles.

Sonic Sifters

- Sonic sifters utilize swift sonic energy pulses to create oscillations within the air column inside the sieve stack. Combined with programmable tapping, this agitation method ensures accurate separations, even for materials as fine as 5μm.

Circular Shakers

- Circular shakers transport the sieve stack along a level, oscillating surface, enabling particles to drop through openings in an unpredictable fashion. Circular motion is wellsuited for coarser materials falling within the range of No. 4 (4.75mm) to No. 100 (150μm). Models that combine circular and tapping actions deliver enhanced performance.